For repairing high pressure mains by the safest, best, and cheapest method

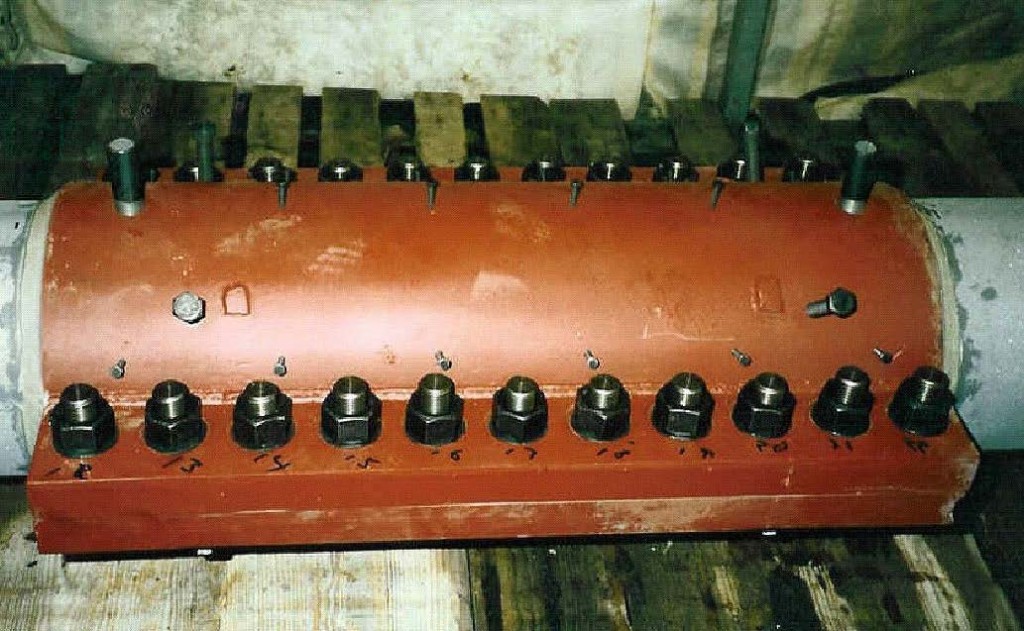

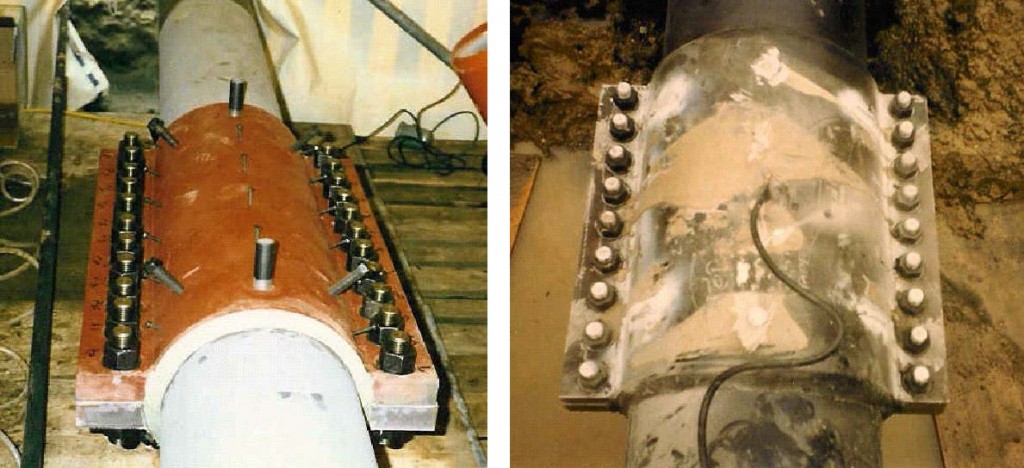

The epoxy shell repair system comprises of two half shells which are joined to encircle the damage, leaving a large, annular gap. This gap ensures that even severely distorted pipelines can be repaired.

The shells have the same thickness and grade as the pipeline, and are at least one diameter longer than the damage.

The ends of the shell are sealed with a putty material and the cavity injected with a high stiffness epoxy grout

The repair prevents radical bulging associated with damage failure.

It also sheds stress into the shell, which reduces both cyclic stresses near the damage and hence locally increases the pipelines’s strength and fatigue life.

Benefits;

- Simple, rapid, proven, and safe repair method

- Any damage is fully restrained

- No welding is required on the live pipeline

- The annular gap between the pipeline and shell is large, which simplifies the manufacture and eliminates fit-up problems during installation.

- Technique has a sound track record